Material Resources Planning - MRP

Categories: Logistics Management System

The Kitaron ERP & MES system offers advanced tools for material requirements planning (MRP), essential for minimizing stock and managing production lines to a Just in Time (JIT) approach.

These tools enable enhanced efficiency, improved on-time delivery, and streamlined production processes.

Key Features:

- Recommendations for purchasing and manufacturing items based on order lines.

- Material and item scheduling as needed for production, eliminating the need for storage.

- Purchasing planning for auxiliary items.

- Raw material requirements planning based on minimum stock levels.

- Recommendations for cancellations, acceleration, or delays.

- Graphical display of inventory.

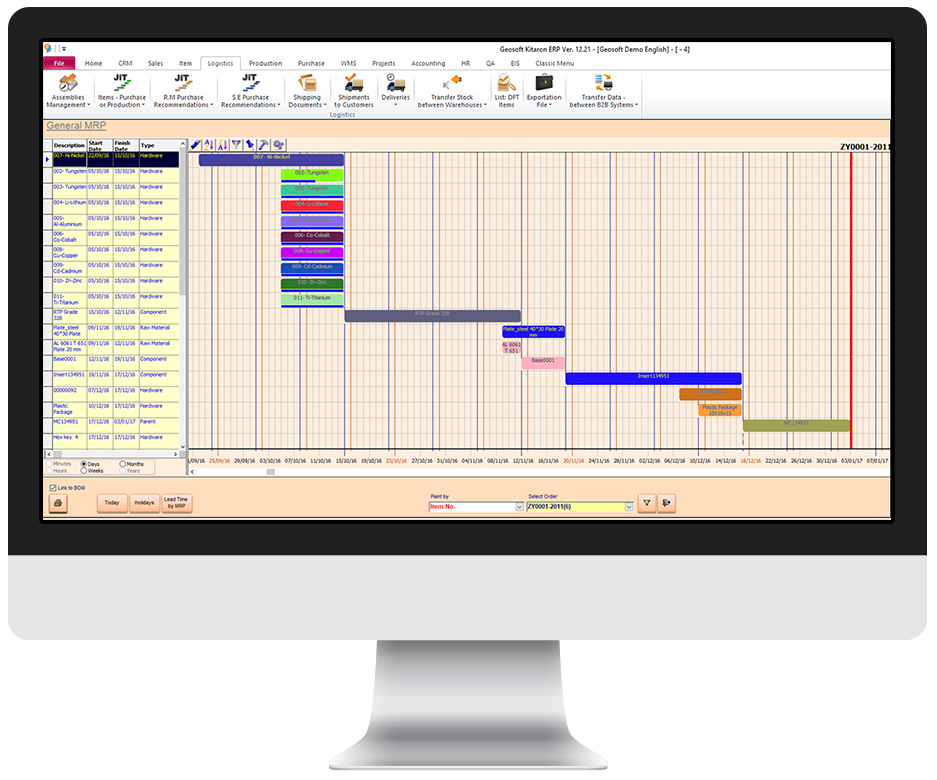

Production Planning by Supply Time (MRP) Gantt

- Recommendations for purchasing and manufacturing items based on warehouse stock, production floor, stock withdrawals, minimum stock, and open purchase orders.

- Centralized recommendations for purchasing and manufacturing items at the item level within specific timeframes.

- Just In Time (JIT) material and item scheduling as required for production.

- Actual production scheduling.

- Purchasing planning for auxiliary items and order lines in a centralized manner.

- Raw material requirements planning based on minimum stock levels for order lines.

- Management of raw materials supplied by the customer.

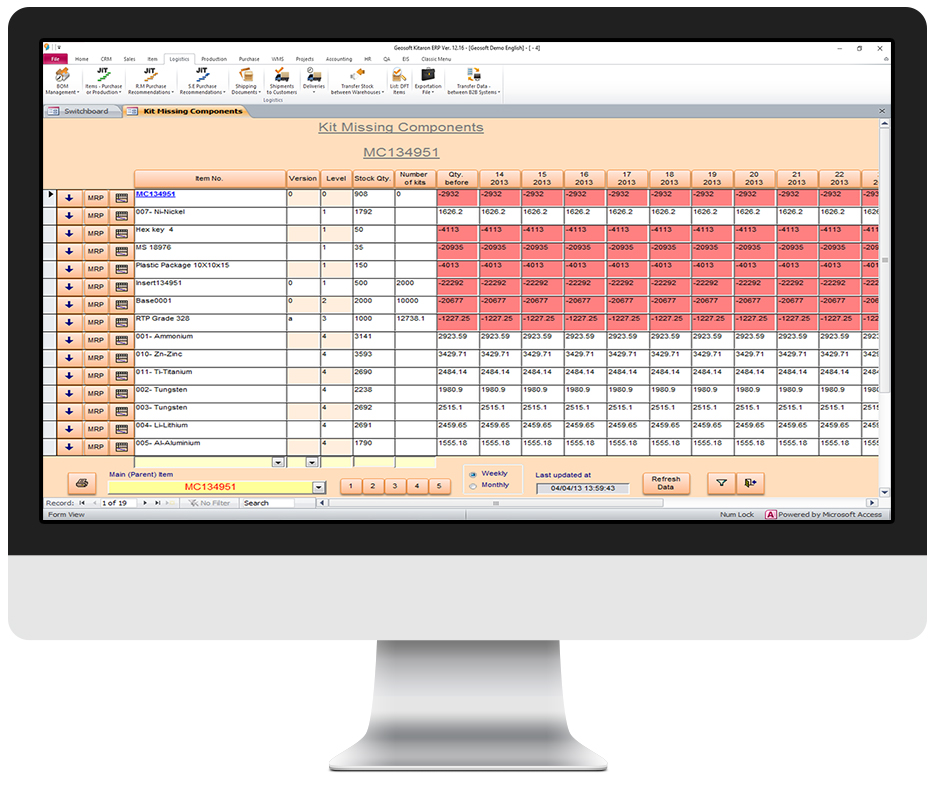

Kit Missing Components

- Recommendations for cancellation, acceleration, or delay of production or purchase orders.

- Cumulative inventory planning.

- EQM requirements horizon for remaining cumulative inventory.

- Weekly or monthly visibility into stock availability for assembly assembly planning.

- Display of remaining cumulative inventory for a given date, considering stock movements.

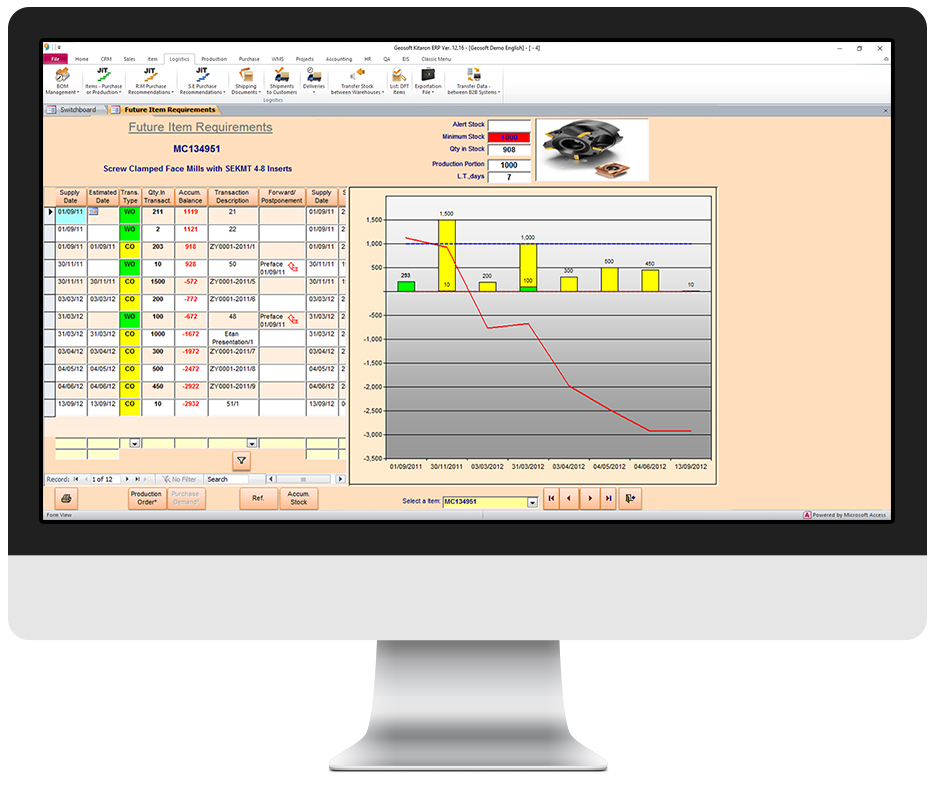

Future Item Requirements

- Graphical display of inventory management, considering minimum stock levels and future inventory movements.

- A comprehensive solution for warehouse and inventory management, including freezes for order lines and blocked warehouses.

- Ability to schedule items outside the MRP.

- Definition and management of warehouses not participating in MRP.

- Monitoring of customer warehouses and material withdrawals for customers.