Data Collection

Categories: Production Management (MES) System

The data collection mechanism in the Kitaron ERP & MES system is an essential control tool for continuous evaluation of the organization's operations, efficiency, quality, and adherence to schedules.

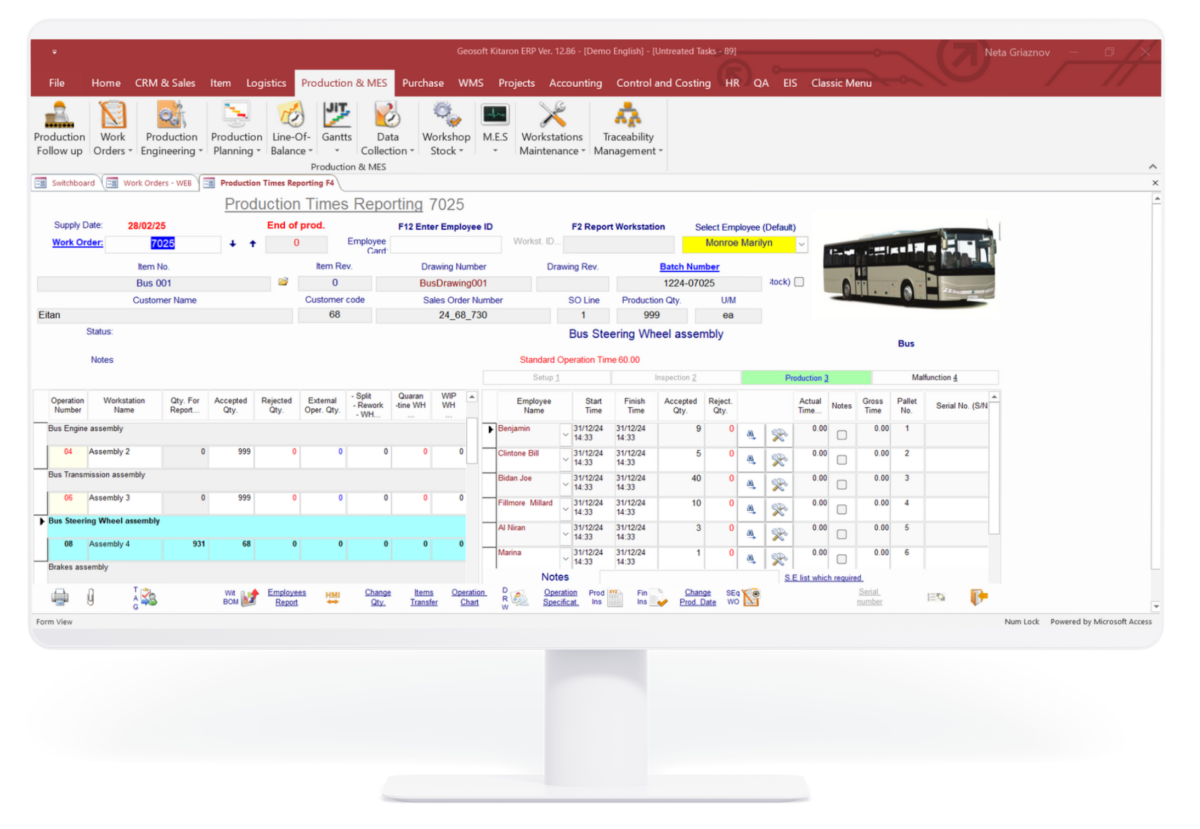

Production Times Reporting

The data collection mechanism allows for tracking and auditing the quantity of good products and reasons for rejection on the production floor. By receiving real-time data from the production floor, the system compares actual occurrences and results against the expectations set by the organization in advance, serving as a tool for evaluating the organization's performance and achievements. This enables the organization to reduce production process defects, identify and correct deviations, and assess the extent to which the organization's potential is being utilized, with a continuous focus on improvements.

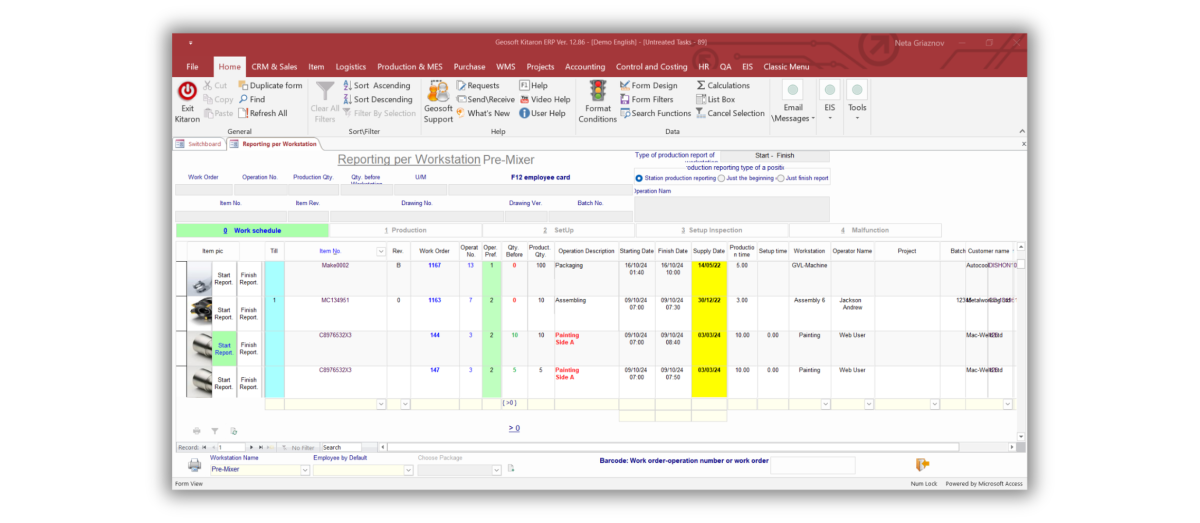

Paperless Production Station – Developed to provide real-time insights and solutions for better management of complex manufacturing environments, eliminating the need for printed documents required on the production floor, such as production plans, engineering drawings, specifications, test requirements, production orders, and more.

• Real-time display of the work schedule at each individual workstation.

• Improved communication between offices and the production floor.

• Continuous improvement in the working environment for production employees.

• Provides real-time insights for performance improvement and operational efficiency optimization.

• Cost and time savings improvement.