Batch Numbers Management

Categories: Production Management (MES) System

Batch Management

Kitaron ERP & MES system empowers your production process by seamlessly assigning batch numbers to each production batch, ensuring precise identification and effortless tracking of every item produced within that batch. This enhances visibility, control, and traceability, helping you optimize operations and improve efficiency across the board.

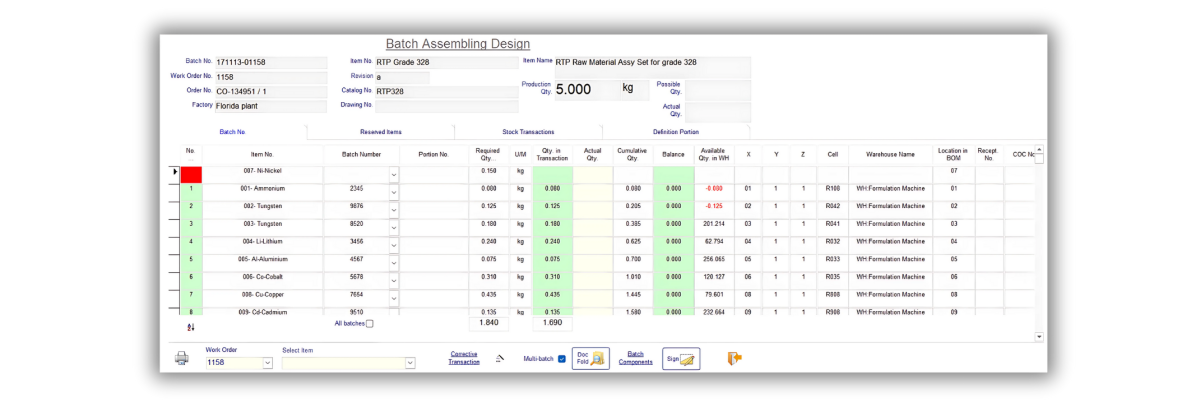

The system enables the definition of batch numbers for assemblies, sub-items, and raw materials, as well as the creation of a batch number tree, including the assignment of raw material batch numbers to production orders and inventory management by batch numbers. In cases where a particular batch is further subdivided, each sub-batch is also assigned a unique identifier, which can be documented and managed according to batch numbers.

The Batch Management module in Kitaron includes the following processes:

• Creation of batch numbers for items.

• Batch number assignment in production orders.

• Batch numbers for pulling product trees from inventory for assembly production.

• Defining batch numbers during goods receipt into the warehouse.

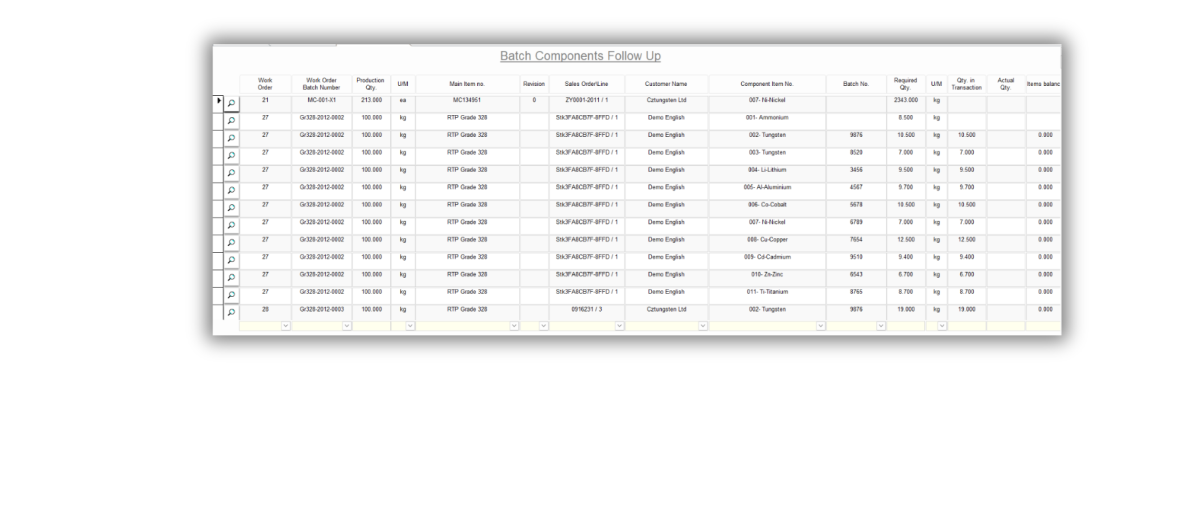

• Inventory movement tracking in warehouses, showing both the production order batch number and the batch number assigned during goods receipt.

• Pulling sub-components for production orders by batch numbers during production – employees report which batches were used and automatically pull the respective batches during reporting.

Batch Definition

Batch Traceability